Multilayer Insulation For Spacecraft Applications, Launch Vehicles, and Cryogenic Applications

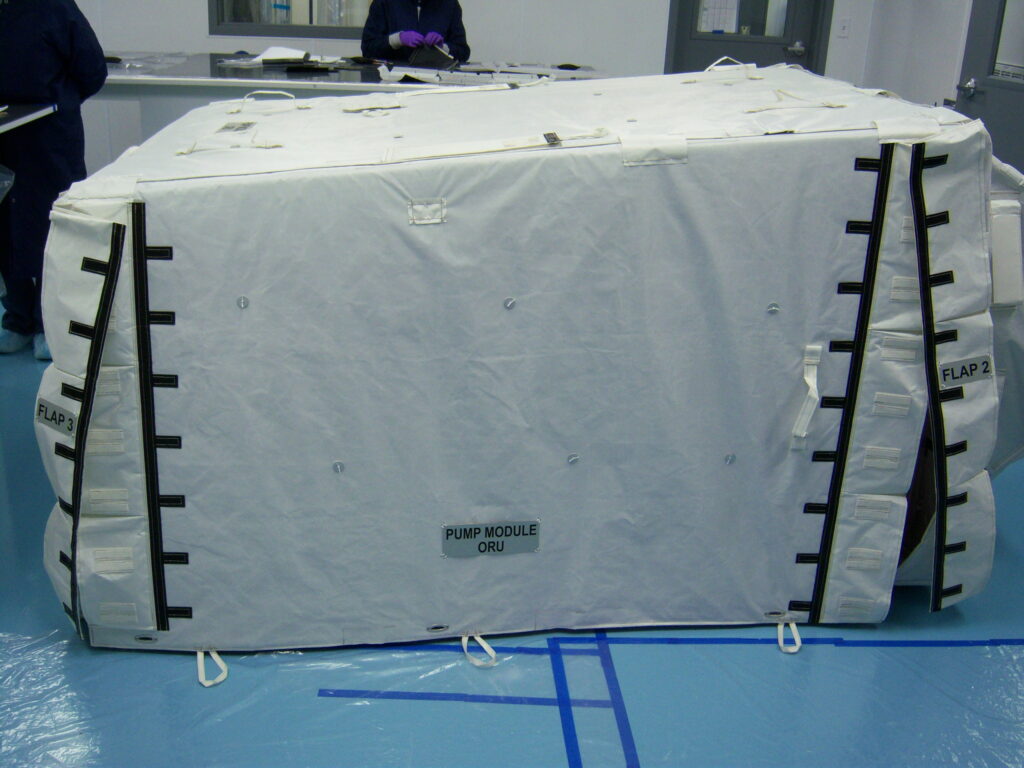

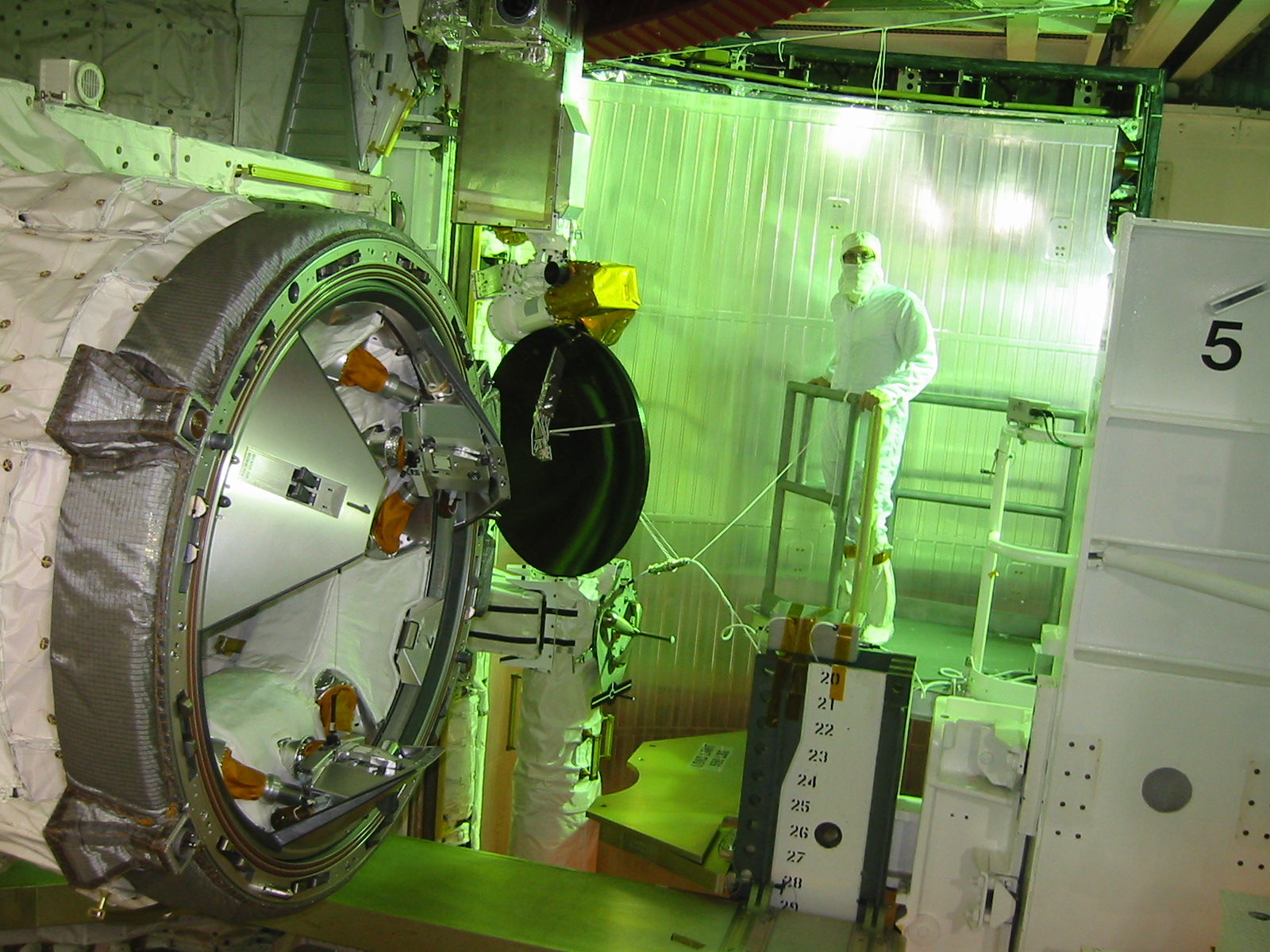

Our staff of engineers and technicians have extensive experience building, and custom fitting multilayer insulation (MLI) for a wide variety of customers with both build-to-print and design-to-fit projects. Our facility is uniquely designed, with a flexible manufacturing system, to produce MLI blankets in custom sizes and shapes for use on spacecraft, launch vehicles, and cryogenic applications where extreme temperatures are present. Specifications for MLI blankets should be provided along with drawings, templates, and/or CAD files. We can also translate file formats for use on our automated cutting system. We have procedures for handling both DPD and MBD requirements. We are skilled at manufacturing either sewn blankets with fabric surfaces or taped blankets with plastic layers. Various sewing and taping techniques can be employed, and combinations of each can be used to produce the best thermal insulation blankets required by your mission.

MLI Blankets for Satellites, Spacecrafts, and More

Our MLI blankets have been used on countless spacecraft and satellites, from Low Earth Orbit to Geostationary Orbit and beyond. Aerospace Fabrication & Materials has produced MLI for “Big Science” missions, individual satellites, and constellations of satellites as well as the International Space Station, which has MLI and shields on the lab, airlock, nodes, and various truss elements.

AFM’s Services: Multilayer Insulation For Cryogenic Applications

Our engineers and multilayer insulation technicians will work with you to perform the appropriate trade studies, examining which materials, optical properties, and thickness will be best suited in a MLI blanket for your upcoming mission. Contact AFM today for MLI design details and specifications and see how we can help make your aerospace insulation blankets a reality.

Learn more about AFM’s capabilities and services—from multilayer insulation to cryogenic testing—by downloading our PDF: