Aerospace Precision Cleaning

Aerospace Fabrication & Materials provides cutting-edge, environmentally-friendly cleaning solutions for aerospace components, thin films, and optical surfaces. We work closely with our customers to implement cleaning solutions that meet the specification requirements for mission success. Our precision cleaning service meets product cleanliness levels dictated in IEST-STD-CC1246. Learn more about our precision cleaning services below:

Precision Cleaning Services at AFM

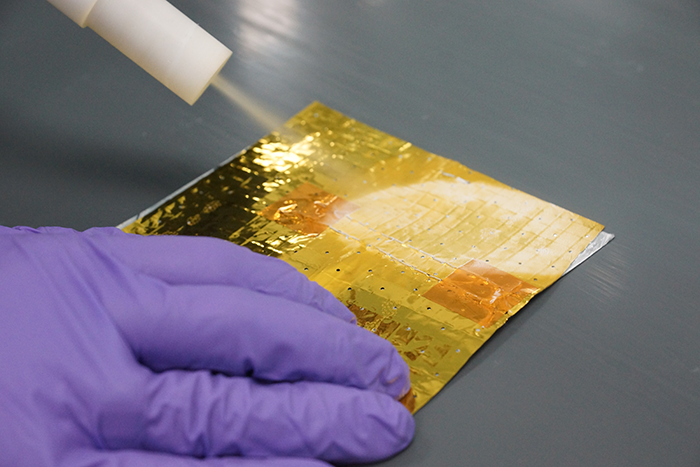

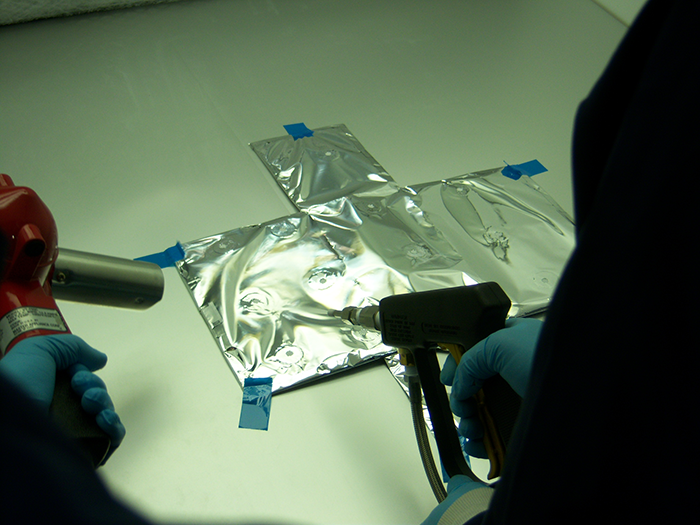

AFM specializes in precision cleaning of flexible aerospace parts, thin films, and other optical surfaces. We use processes including delicate surface wiping, vacuum bakeout, and CO2 snow cleaning to remove contaminants.

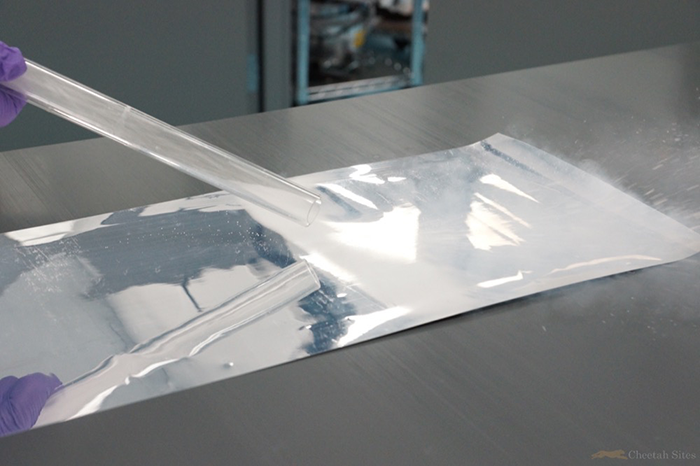

Delicate surface wiping uses special lint-free wipes in concert with solvent or deionized water to gently remove contaminates from the surfaces of fragile components.

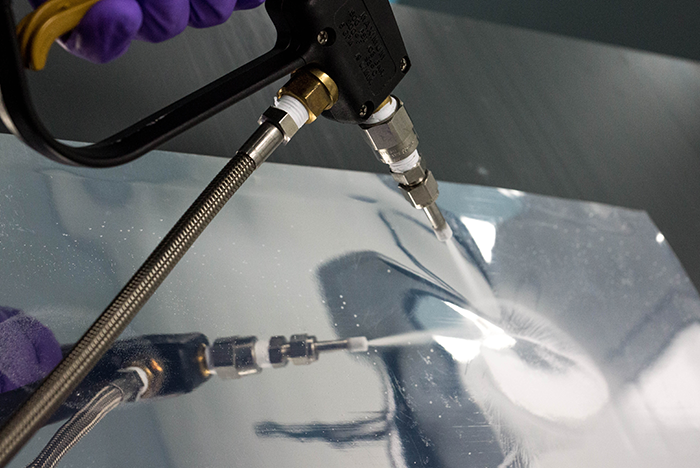

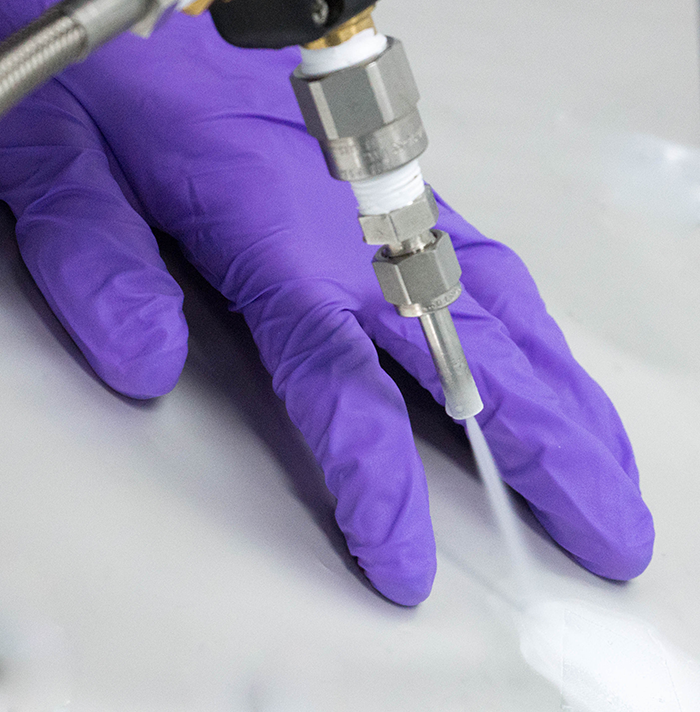

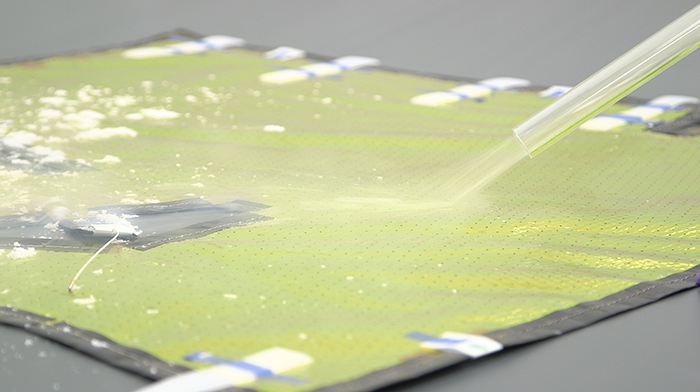

CO2 snow cleaning is a non-abrasive cleaning method. This process uses a high-velocity CO2 solid and CO2 gas to remove insoluble particles from surfaces. The high-velocity flow exceeds the adhesive force, causing the particles to be swept away with the gas flow. Organic compounds are also dissolved and removed from the surface.

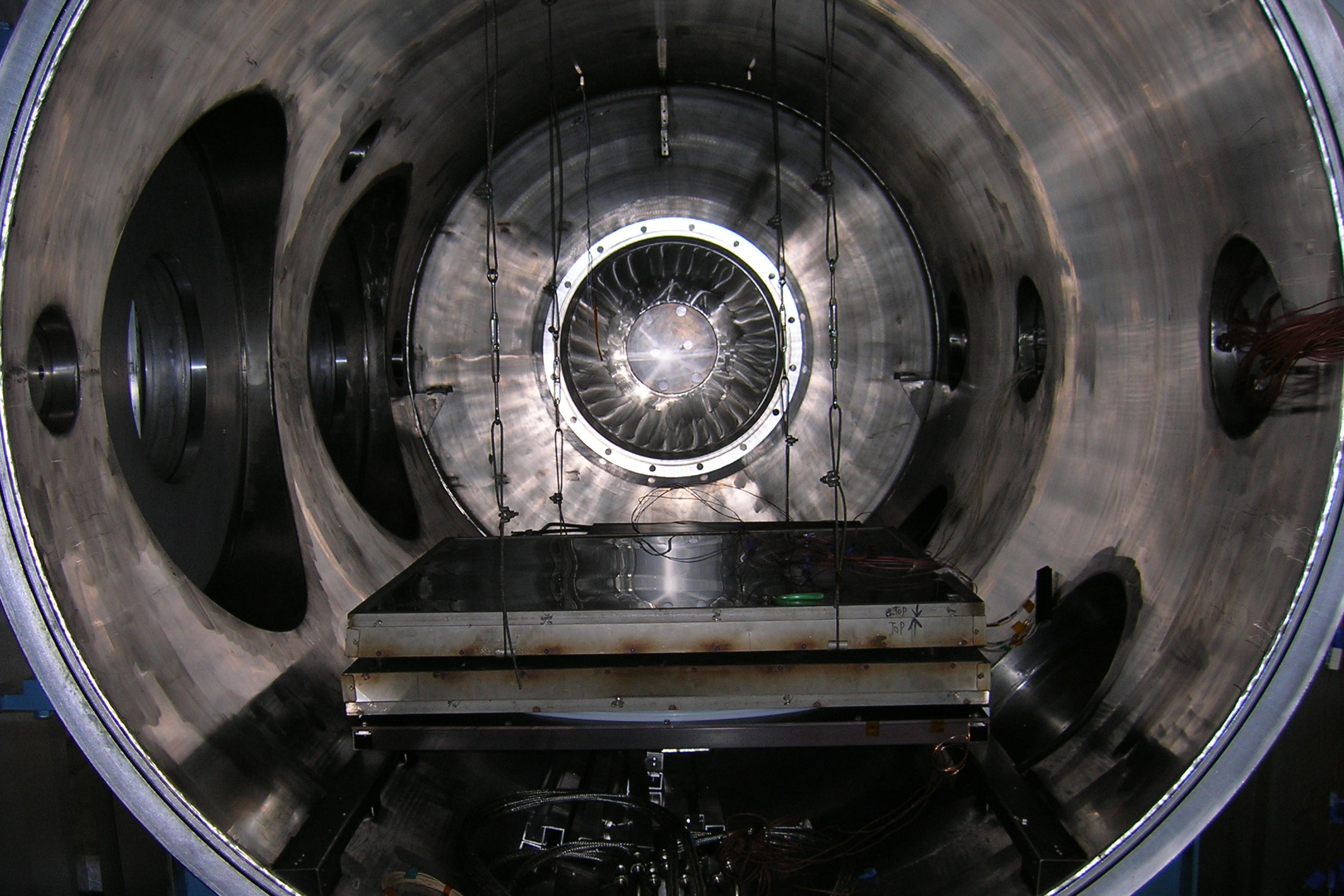

These methods coupled with an additional vacuum bakeout service provides a product that meets the most stringent specification requirements. Learn more about vacuum bakeout here.

CO2 Snow Cleaning: The Future of Aerospace Precision Cleaning

Carbon dioxide snow cleaning, also known as CO2 blasting or dry ice cleaning, uses solid carbon dioxide (CO2) pellets or snow to remove contaminants from various types of surfaces. The process is dry and solvent-free, making it environmentally friendly and suitable for use in sensitive applications in optics or aerospace applications.

CO2 snow cleaning is:

- Non-abrasive and leaves surfaces residue-free.

- A high-precision cleaning process that removes large and small particulate contamination.

- A cleaning process that removes a variety of organic compounds including oily films, grease fingerprints, and flux residues.

- Useful for thin film surface cleaning and sensitive optical surfaces.

Interested in learning more about our precision cleaning services and capabilities? Contact one of our technical staff to learn more.

Customers Also Viewed